The report "Passive Fire Protection Coatings Market

by Type (Intumescent, Cementitious), Technology (Water-Based,

Solvent-Based), End-Use Industry (Building & Construction, Oil &

Gas, Transportation), and Region - Global Forecast to 2022",

The passive fire protection coatings market is projected to reach USD

4.02 Billion by 2022, at a CAGR of 6.6% from 2017 to 2022.

The use of passive fire protection coatings has increased due to stringent government regulations regarding the usage of passive fire protection coatings and fire safety standards. In addition, the rapidly growing building & construction industry is expected to lead to an increase in the demand for passive fire protection coatings. Oil & gas and transportation are the other industries which demand passive fire protection coatings.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownload.asp?id=165549042

The use of passive fire protection coatings has increased due to stringent government regulations regarding the usage of passive fire protection coatings and fire safety standards. In addition, the rapidly growing building & construction industry is expected to lead to an increase in the demand for passive fire protection coatings. Oil & gas and transportation are the other industries which demand passive fire protection coatings.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownload.asp?id=165549042

The intumescent coatings type fire protection

coatings segment accounted for the largest share of the passive fire

protection coatings market in 2016

Intumescent coatings type fire protection coatings

was the largest type segment of the passive fire protection coatings

market, in terms of value in 2016. This high market share is mainly

attributed to its usage across various applications, such as commercial

buildings, restaurants, hospitals, colleges, residential buildings,

skyscrapers, and offices, and the oil & gas industry, among others.

The value market of intumescent coatings is higher as compared to

cementitious coatings as, intumescent coatings are used in combination

with cladding materials. Intumescent coatings require lower maintenance,

improve durability, provide longer shelf-life, and also provide

corrosion protection for steel structures in buildings. Hence, these

properties of intumescent coatings are expected to foster the growth of

these type of coatings in the passive fire protection coatings market.

The water-based technology of fire protection

coatings accounted for the largest share of the passive fire protection

coatings market in 2016

The water-based technology segment of the passive

fire protection coatings market accounted for the largest share, in

terms of both, value and volume, in 2016. Water-based fire protection

coatings are extremely safe as they do not contain harmful solvents, are

low odor and have low VOC emissions. These are developed to enable

customers to meet the stringent emission standards set by various

agencies, such as, Registration, Evaluation, Authorization, and

Restriction of Chemicals (REACH) and the Environmental Protection Agency

(EPA). Also, these water-based coatings can withstand high humidity

levels during application. The above factors are fueling the demand for

the water-based technology in the passive fire protection coatings

market.

Request For FREE Sample Pages @ https://www.marketsandmarkets.com/requestsample.asp?id=165549042

The market for fire protection coatings in

the building & construction industry is expected to grow at the

highest CAGR during the forecast period

The building & construction industry is expected

to register the highest growth, in terms of both, value and volume

during the forecast period. Fire protection coatings are used in

buildings owing to the various benefits that these provide. These

coatings prolong the time period of damage that could be caused,

providing ample time to evacuate a building in case of fire. Moreover,

these also help in the protection of firefighters while controlling the

fire and hence help reduce damage to a structure and loss of assets.

Building & construction is one of the major

applications of passive fire protection coatings. These are used in

construction activities to protect buildings to enable withstanding

fire. Such coatings are applied so that the steel structures used in

building & construction can withstand a fire and prevent the steel

from reaching the critical temperature which could lead it to collapse.

Passive fire protection coatings are mainly used in high rise buildings,

sports stadiums, residential, and commercial construction.

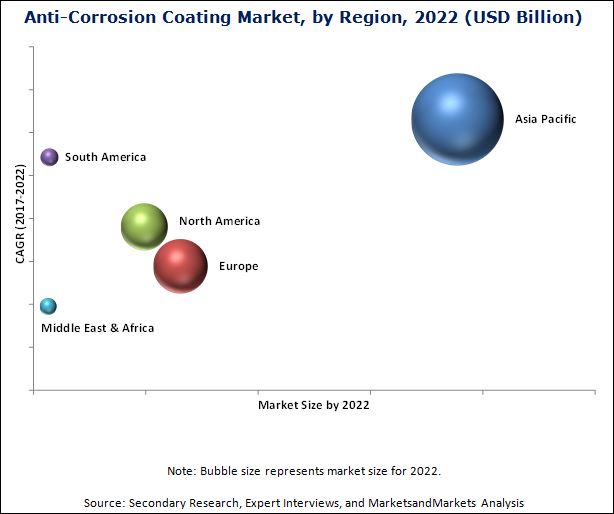

The passive fire protection coatings market

in the Asia-Pacific is expected to grow at the highest CAGR during the

forecast period

The Asia-Pacific is the largest market for passive

fire protection coatings, in terms of both, value and volume, and is

expected to be the fastest-growing region. Increasing industrialization

and end-use industries are expected to lead to an increase in the demand

for passive fire protection coatings in this region. The booming

construction industry is expected to drive the demand for passive fire

protection coatings in buildings in the public and private sectors in

this region. The regulations in this region are a driver for the passive

fire protection coatings market. Moreover, the rising middle-class

population coupled with increasing consumer spending has further

contributed to the high demand in Asia-Pacific countries, such as China,

Japan, and India.

Key players in the passive fire protection coatings market

Key players operating in the passive fire protection

coatings market include Akzo Nobel (The Netherlands), PPG Industries

(US), The Sherwin-Williams Company (US), Promat International (Belgium),

Carboline (US), Hempel A/S (Denmark), KANSAI PAINT (Japan), Nullifire

(UK), Jotun (Norway), and Teknos Group (Finland).